What does our Technology do ?

The overall Flash Rockwell system is a low-pressure / low-thermal industrial drying system. The heart of the system is the Company's patented "Flash Generators" concepts consisting of both our Dorothy™ and our Nested Venturi™ processing system designs. Our systems can include pre and post processing materials handling equipment to create an end-to-end solution to meet most any customer demands. Virtually any Liquids or Solids media stream can be processed with accurate precision.

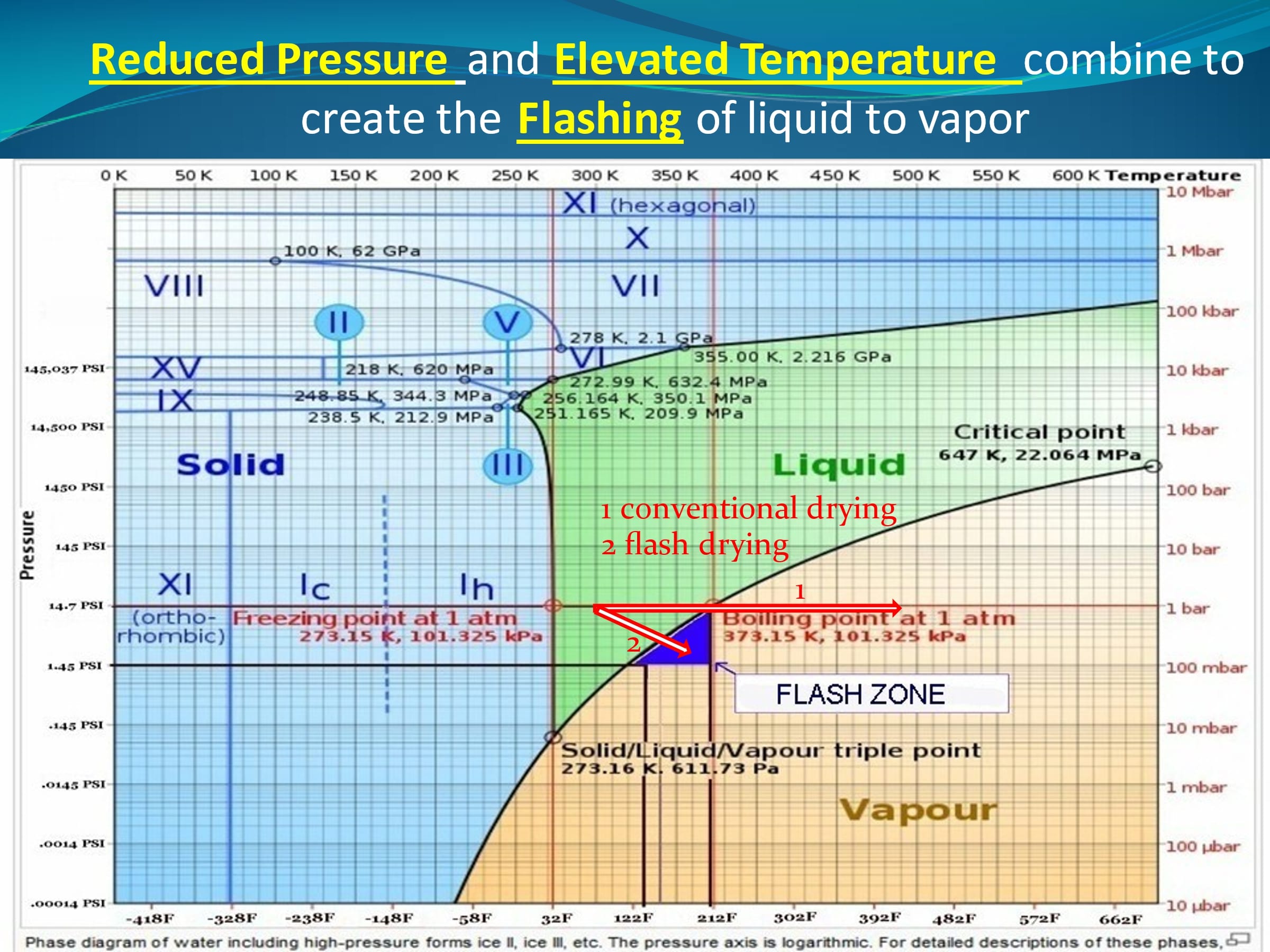

Flash Rockwell’s revolutionary methodologies de-water and dry nearly every solid, suspended solid, or dissolved solid, utilizing a controlled sub-atmospheric pressure environment. Our process is powered using traditional off-the-shelf air blowers to compress ambient air that ultimately create heat and pressure changes. We control and direct airflows which create rapid pressure loss. Our systems produce a processing environment where water physically cannot exist in a liquid state.

Depending on the individual properties and vapor pressure / temperature relationship, it is possible to limit the release of Volatile Organic Compound (VOC) pollutants contained in the subject materials we dry. Flash Rockwell’s process can be preset or dynamically adjusted to vary pressure and temperature conditions. The vapor pressure and temperature at which various VOC’s vaporize can be avoided maintaining the VOC pollutants in a stable state. The potential advantage for avoiding VOC release should be considered for each application with regard to the anticipated VOC’s present in each specific customer material stream.

The Flash Rockwell Flash Drying process provides accurate control capability with limited introduction of heat to the subject material. We have shown that a reduction in air pollutant discharge is achievable over traditional and polluting thermal drying systems. Limiting pollutant discharge from the process will in turn provide greater flexibility in modifying current Title V Air Quality Permits or obtaining new permits, and further, may serve as a reason for the replacement of existing and polluting standard thermal drying processes. Flash Rockwell’s technology can provide a reduction in overall plant pollutant discharge providing opportunities for non-compliant facilities to achieve compliance.

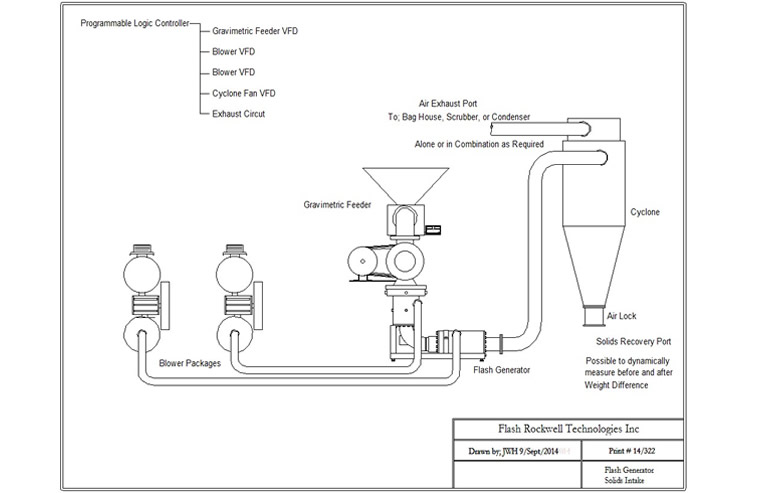

Flash Rockwell’s proprietary processing system consists of the following components:

• Lobe, Screw or Pressure Blower Packages – These Blower Packages are the heart of our system. They are designed for the efficient generation of high volume, high velocity “dry heated air” at relatively low back pressure of 3 to 10 PSIG.

• High Pressure In-Line Air Heater designed for the efficient heat addition to the process airstream as the specific process may require. The additional BTU added to the process air provides enhanced production capabilities utilizing the same volume of airflow. Fuel sources are flexible to take advantage of the most cost-effective energy source available.

• Feed Hopper – This vessel, holds, monitors, and meters, material at environmental ambient conditions. Installed sensors transmit dynamic conditions, such as ambient air pressure, material moisture levels, material weight, barometric pressure, and ambient humidity, to the programmable logic controller.

• Programmable Logic Controller (PLC) – The PLC monitors and controls feed rates, moisture reduction levels, temperature levels, pressure conditions, agitation cycles, and air velocities by dynamically adjusting all operating parameters to achieve the highest level of efficiency possible. We can include a post scale so our customer knows the amount of water loss achieved in real time.

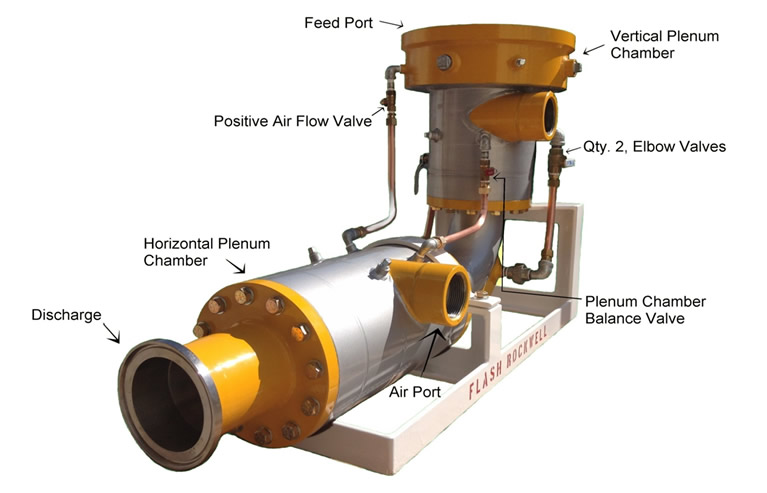

• Feed Hopper Air Lock – The Feed Hopper Air Lock separates the ambient environmental conditions in the Feed Hopper from the modified and controlled conditions of the Sub Atmospheric Pressure Area of the Flash Generator.

• Flash Generator – Our Flash Generators can be used as a dryer/conveyor, or a moisture digester. Our process uses very high velocity 200F+air streams and induced vacuum conditions that measure between 4.4 PSIA to 10 PSIA. This proprietary technology creates operating conditions in which moisture cannot exist in a liquid phase. Once materials or vapors pass through our flash generator they are subjected to cyclonic separation, and a material recovery system which can include baghouses, scrubbers and/or condensers if a customer chooses to re-claim and re-use liberated moisture.

How does our process work ?

Flash Rockwell utilizes well-understood and proven physics related to phase and vapor pressure conditions. Our technology can dry materials with both inherent and surface moisture. Our operating principals can be utilized to process virtually any media by reducing the ambient atmospheric pressure and slightly increasing the temperature, creating a highly efficient drying operating system. As shown below in the water phase diagram, water cannot exist in liquid state within the ‘Flash Area’ highlighted below.